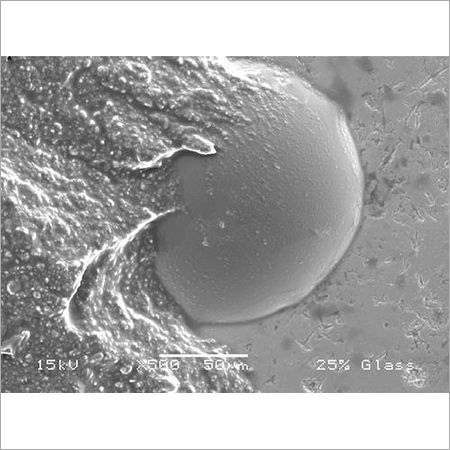

Surface Preparation Glass Bead

Price 65 INR/ Kilograms

Surface Preparation Glass Bead Specification

- Finish Type

- Matt, Satin, Uniform Finish

- Strength

- High Impact Resistance

- Transparency

- Translucent

- Tolerance

- 0.02mm Millimeter (mm)

- Structure

- Solid Bead Structure

- Features

- Non-toxic, Recyclable, Inert, Dust-free

- Glass Type

- Industrial Blasting Glass

- Material

- Glass Bead

- Thickness

- Customizable (commonly 0.05mm 0.5mm) Millimeter (mm)

- Weight

- Varies (typically 0.1kg 25kg bags) Kilograms (kg)

- Surface

- Smooth, Round

- Density

- 2.5 Gram per cubic centimeter(g/cm3)

- Composition

- Soda-lime Silicate Glass

- Technique

- High-pressure Jet Peening

- Pattern

- Uniform Spherical

- Melting Point

- 1400C

- Reusability

- Multiple Cycles Possible

- Moisture Content

- <0.02%

- Hardness

- Mohs 5.5 6

- Usage Environment

- Metal, Glass, Ceramic, Plastic

- Color

- Clear

- Particle Size Range

- 0.1mm 2.5mm

- Application

- Surface cleaning, finishing, deburring, peening, shot blasting

- Packing Type

- Bags or Drums

Surface Preparation Glass Bead Trade Information

- Minimum Order Quantity

- 25 Kilograms, ,

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 30 Kilograms, , Per Month

- Delivery Time

- 4 Week

About Surface Preparation Glass Bead

Product Specification

Usage/Application Shot blasting, shot chrome

Material To Be Blasted Plate

Brand VISHAL GLASS SHOTS

Size 2 Microns

Color White

Shape Rounds

Material Glass

State Crystals

Minimum Order Quantity 500 Kg

Product Description

Supplier & prepared of Glass Beads For Sandblasting. Our product range comprises of glass beads for shot blasting, glass beads for peening and deburring, glass beads for surface preparation & glass beads for grinding of paints, chemicals, pigments, fertilizers, minerals, etc.

Features:

It provides a smooth and economic cleaning

It fits frequent cleaning

It is used on welding surface

It removes surface oxidation, flame stains

Additional Information

Delivery Time 2 TO 3 DAYS

Production Capacity 15000

Packaging Details 25 KG PP BAGS

Superior Surface Finishing and Cleaning

Glass beads offer non-toxic, dust-free performance with high impact resistance, making them ideal for gentle yet effective surface cleaning, finishing, and deburring. Their uniform spherical shape ensures consistent results, while leaving surfaces smooth and free from contaminants.

Customizable and Reusable Media

Available in various particle sizes and thicknesses to fit specific needs, these beads are recyclable and can be used for multiple blasting cycles before replacement. High durability and inertness contribute to sustainable and cost-effective surface preparation processes.

Versatile Application Across Industries

Engineered for use on metals, ceramics, plastics, and glass, glass beads deliver matt, satin, or uniform finishes suitable for industrial, automotive, and decorative applications, ensuring reliable performance whether for cleaning, peening, or finishing tasks.

FAQs of Surface Preparation Glass Bead:

Q: How are Surface Preparation Glass Beads typically applied in industrial environments?

A: Surface Preparation Glass Beads are applied using high-pressure jet peening or shot blasting equipment to clean, finish, deburr, and strengthen surfaces of metals, ceramics, plastics, and glass. Their uniform spherical structure ensures even coverage and consistent surface treatment.Q: What benefits does using glass beads provide over other abrasive media?

A: Glass beads offer several advantages, including being non-toxic, dust-free, inert, and recyclable. They produce a smooth, satin, or matt finish without damaging base materials, and their high impact resistance ensures longevity and cost efficiency through multiple reuse cycles.Q: When should glass beads be preferred for surface cleaning or finishing?

A: Glass beads are ideal when a gentle yet thorough cleaning, deburring, or finishing is required without altering the substrates dimensions or integrity. They are especially suitable for applications needing a uniform, non-abrasive and attractive finish on metals, glass, ceramics, or plastics.Q: Where can one source these glass beads in India for industrial use?

A: Surface Preparation Glass Beads are available through reputable exporters, manufacturers, and suppliers based in India. They are typically supplied in bags or drums, accommodating various project scales, from small workshops to large industrial operations.Q: What is the process of reusing glass beads, and how many cycles are possible?

A: Glass beads maintain their shape and strength over multiple cycles due to their solid bead structure and high impact resistance. They can be collected, cleaned, and reused in subsequent blasting operations until their performance begins to diminish, maximizing value and sustainability.Q: Is it possible to customize the thickness and size of these glass beads for specific applications?

A: Yes, manufacturers can supply glass beads in customizable particle sizes (0.1mm2.5mm) and thicknesses (commonly 0.05mm0.5mm) with precise tolerance (0.02mm), ensuring a tailored solution for distinct industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry